PCR Film

Solution Group

- Products

- Services

- Integration

- Automation

-

pack

-

bundle

-

unitize

-

warehouse

-

transport

Regional Availability

_1.png)

Sustainability

First

Reduces waste by material made with 30% PCR content, recovered from post consumables waste stream.

Future

Ready

As all industries look how to protect the planet, film is no different. PCR Film reduces the use of fossil fuels.

CO2

Reduction

Using less fossil fuels in the production process we are mimimising CO2 emissions.

Plastic

Compliance

As the EU and other countries introduce plastic taxes, using Post Consumer Recycled plastic material may reduce your tax burden.

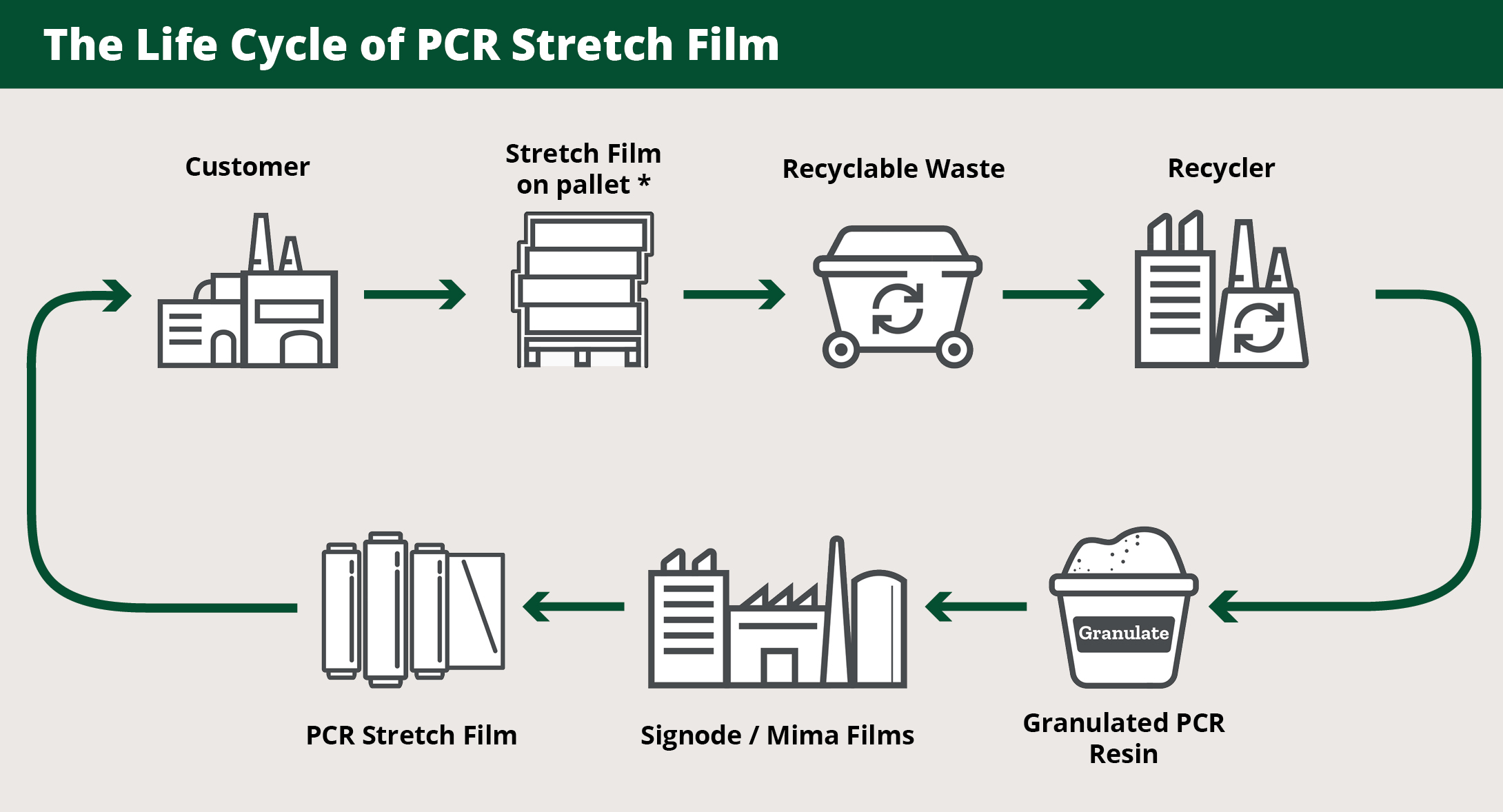

Post Consumer Recycled Film

Available as both stretch and oriented films, the Post Consumer Recycled (PCR) film range is a great sustainable solution for your business.

Collection of waste from industrial packaging supports the production of PCR Resin which is needed to create the sustainable product of PCR film. Even the return of pre-used oriented film can be utilised to gain the resin required to make PCR film. PCR Resin is collected from our partners with the highest grade quality considered leading to the same mechanical properties of non-PCR film.

Signode PCR stretch film is an eco friendly stretch film, created from recyclable waste repurposing PCR resin into a strong and sturdy plastic stretch film. If you want to find out more information about PCR Stretch film make sure to to reach out to our team. Our film solution is suitable for use on Signode stretch wrapping machines such as the Octopus® Compact and also hand applications.

Due to our quality research and development, normal fossil fuel based oriented film and PCR have the same performance qualities. By using 30% PCR Resin we are confident to produce a reliable and consistent product. Manufacturing of PCR film occurs in a loop, from the recycling plant of our trusted suppliers we product PCR film which our customers will apply onto a pallet and eventually once being used will be able to send back to the recycling plant.

* Fossil fuel based and PCR stretch film can be recycled several times in this loop

PCR Stretch Film Technical Specifications

| Specification | Cast Film | Blown Film |

|---|---|---|

| Thickness | 17 / 20 / 23 | 17 / 19 / 22 |

| Width (mm) | 500 | 500 |

| Length (m) | Up to 2300 | Up to 2300 |

PCR Oriented Film Technical Specifications

| Specification | Hand Film | Machine Film |

|---|---|---|

| Thickness | 6.6 | 6.6 |

| Width (mm) | 390 | 390 |

| Length (m) | Up to 800 | Up to 4200 |

Solution Group

- Products

- Services

- Integration

- Automation

-

pack

-

bundle

-

unitize

-

warehouse

-

transport