Automation & Integration

Complete Solutions for End of the Line Packaging and Warehouse Automation

Discover the advantages of turn-key installation, one-supplier convenience, and product versatility.

Thousands of customers worldwide rely on our automated equipment solutions to complete their most efficient production lines. From material handling and conveying solutions to our unitizing, strapping, and stretch equipment, Signode offers the tools to achieve greater automation for an optimized total systems approach.

Signode’s automation solutions include:

- In-plant Automation

- End-of-Line Packaging Automation

- Material Handling and Conveying

- Warehouse Automation

- Industry 4.0 / IoT

- Automated Storage and Retrieval Systems

- Warehouse Management/Track and Trace

- Automatic Guided Vehicles

- Last-Mile Delivery Apps

- Pick and Pack / Sortation

-

StorfastStorfast Overview Video

-

StorfastStorfast Video

-

Automation System rendering video screenshotEnd-of-the-line Automation Video

-

Automation and Packaging TechnologiesAutomation and Packaging Technologies Video

Our Process

Conduct On-Site Audit

We conduct an on-site review of your packaging lines to understand your challenges and opportunities for improvement.

Design Optimal Solutions

We supply process, software, and equipment recommendations that are field-tested in our ISTA-certified labs for validation.

Execute the Concept

We work with you to commission equipment, set up automation, configure software, and train your people with minimum downtime.

Service and Support

We facilitate service and operator training, schedule preventative maintenance, and provide on-site support to optimize efficiencies.

The Result

Signode delivers the lowest total cost of ownership and the highest overall equipment effectiveness; optimizing product protection and ROI.

Featured Solutions

Maximizing Warehouse and Operational Efficiencies with StorFast® ASRS

Move pallets in and out of storage positions quickly and automatically with Signode’s StorFast® ASRS warehouse system. This high-density solution for “lights out” warehousing provides increased throughput and flexibility with limitless configurations. Automated shuttle/cart system allows multiple orders to be processed simultaneously and flexes between high-volume input and peak shipping schedules to optimize utilization and efficiency.

Robotic Palletizing and Depalletizing

As an authorized system integrator for Fanuc® and several other robotic manufacturers, we have the relationships and experience necessary to design and integrate the ideal palletizing and/or depalletizing setup for a wide range of applications. We design, manufacture, and integrate custom robotic palletizers and depalletizers for customers around the world.

Every robotic palletizing system we supply is engineered for our customer’s desired speed, service life, payload, reach, repeatability, and affordability to support implementation success.

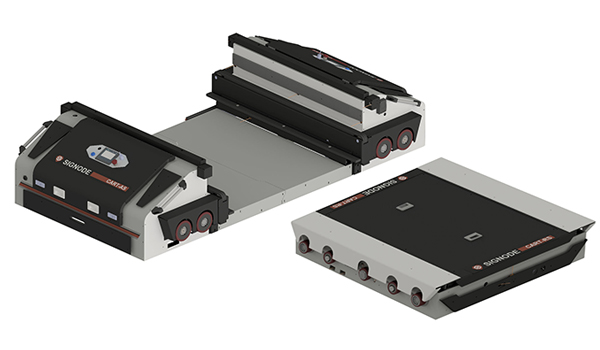

Autonomous Mobile Robots

Autonomous Mobile Robots (AMRs) are designed to optimize productivity in logistics and manufacturing operations. AMRs make your employees more efficient by allowing them to focus on higher-value activities, while shortening lead time, reducing the risk of bottlenecks, and optimizing safety.

As a certified integrator of MiR (Mobile Industrial Robots) we can provide advanced collaborative robotics to automate many manual material handling tasks. An AMR can be equipped with custom end-of-arm tooling (end effectors) to aid in tasks such as material delivery, screw driving, picking and placing, adhering, sorting, and more. AMRs can perform similar tasks at multiple locations on a line utilizing just a single robot, maximizing return on investment, and minimizing initial automation costs. AMRs use cameras, laser-based navigation systems, and collaborative robotics to operate around already-existing features, including plant personnel in a manufacturing environment.

Packaging Automation

Comprehensive packaging automation solutions that can meet a wide range of system needs.

To increase speed to market and throughput, we take the time to understand your unique packaging goals and challenges. This allows us to thoroughly assess your current operation and identify opportunities for packaging automation that support your business needs.

Our extensive product knowledge makes us the first-choice packaging automation solution provider for companies worldwide.

Robotic Case Packing

Robotic case packing leverages repetitive motion capabilities to automate the end of your manufacturing line. Customers expect orders to ship quickly, accurately, and without product damage at high volumes. A smooth and efficient robot case packer ensures security and efficiency with these critical systems.

We design and integrate robotic case packing solutions that are intelligent, flexible, and specific to your product. Increase your throughput with a robotic case packing solution that can pick single or multiple products at a time. We also offer quick change end of arm tooling that can prepare your business to handle future products of varying sizes.

Medical Device and Pharmacy Automation

We offer custom solutions that simplify lab automation, improve utilization of lab resources, increase efficiency, accelerate processing, and achieve consistent end products.

Our highly customizable automated lab systems deliver excellence and expandability for future growth.

Assembly and Test

Our assembly and test products, whether through a fully automated or a tiered approach, drive productivity and profitability.

We can apply our expertise to customize your system and enhance your assembly and test operation for a wide range of applications such as Electronics, Semiconductor, Automotive, Appliance and Medical device

Controlling Assets with Track and Trace

Follow important assets throughout the entire supply chain life-cycle. Complete digital asset management software provides transparency, reliability, and profitability with RFID technology and last-mile GPS integration. This technology enables processes such as returnable asset management, inventory reliability, and product security.

Mec-A-Tec™ Can Handling Conveyor Systems

Full design, manufacture, and installation of technical solutions across a range of conveying equipment. From small to large-scale contracts, we deliver major turnkey projects for leading can and metal packaging manufactures worldwide. Including, but not limited to:

- Mechanical Conveying Systems: Straight running, slat conveying, side flexing, mass conveying, single filing and bi-directional tailored to individual needs.

- Air conveying Systems: Air powered, horizontal, vertical and gravity conveying for high-speed, 2-piece aluminum and steel can and cup handling.

- Vacuum Conveying Systems: Vacuum lowerator, turnover, ski-slope, transfer, single-lane elevators, conveyors, and finished can inspections systems for 2-piece and 3 piece aluminum beverage cans.

- Can Trackwork: Can twists, drop in boots, can gates, and sweeps for machine infeed and discharges.

- Modular Conveying Equipment: Purpose-built, modular units manufactured to your specification to increase productivity, maximize efficiency, and reduce spoilage.

Schedule Your On-Site Audit

Upgrading existing systems or starting from the ground up? Our automation experts are ready to help, from initial assessment and system design to installation and ongoing maintenance. Modern solutions for your changing demands. Discover how Signode’s automation solutions increase efficiency, enhance productivity and improve throughput by contacting us today.