End of Line Packaging Solutions

August 04, 2025

Signode is a leader in providing end of line packaging systems. We provide a solutions focused approach, looking to integrate automation from our wide range of packaging equipment into your facility.

What is End-of-Line (EOL) Packaging?

EOL packaging is the final stage in the production process where products ae prepared for shipment / storage. This process securely packages for transport out of the manufacturing facility. The process to find the best end-of-line solution for each business is unique to the challenges provided according to the composition of the product make up.

The goal is to securely package the product, label the product / load, palletize and prepare for transportation for greater handling, unitization of products into a manageable unit.

As well as providing additional transportation handling solutions to protect the various rigours of global logistics.

This process typically incorporates a blend of some of the the following components:

- Strapping: To secure and unitise products with plastic or steel strap

- Wrapping: Using stretch film or hood film to stabilize and protect loads

- Case Packaging & Labelling: Pack products and automate labelling for improved efficiency.

- Protective Packaging: To be used in combination with our packaging solutions to provide greater pallet security while also offering solutions for confidence of handling

The Signode Approach

At Signode, we take a consultative and data-driven approach to solving your packaging challenges. We begin by conducting a comprehensive packaging audit to understand your specific operational needs, product characteristics, and logistical requirements. This allows us to tailor solutions that not only protect your products but also optimize your packaging line for efficiency and cost-effectiveness.

Our end-of-line packaging machinery is designed with flexibility in mind. Whether you require standalone systems that integrate seamlessly into your existing setup or a fully automated packaging line, we can configure a solution that aligns with your production goals. This process often involves a carefully selected combination of our technologies, including strapping, wrapping, labeling, palletizing, and load containment systems.

We leverage real-time data and analytics to inform our recommendations, so every solutions grounded in measurable performance improvements. From reducing material waste and minimizing downtime to enhancing load stability and throughput, our goal is to deliver packaging systems that evolve with your business.

Dedicated Industry Focused Packaging Approach

Packaging Equipment for Metals

Providing integrated packaging and handling solutions for various metals including Cold Rolled Coils, Hot Rolled Coils, Ingots, Rod and Wire Coils, Sheets, Slit Coils, Tubes, Bars, and Billets. We provide tailored solutions utilizing specialised strapping and wrapping offerings to handle the demands of the metals industry.

Also offering a wide array of material handling equipment all designed to improve operational safety, efficiency, and product protection throughout the metal production and distribution process. Our solutions first approach will utilize the best product mix including protective packaging so metals arrive at their destination according to product requirements.

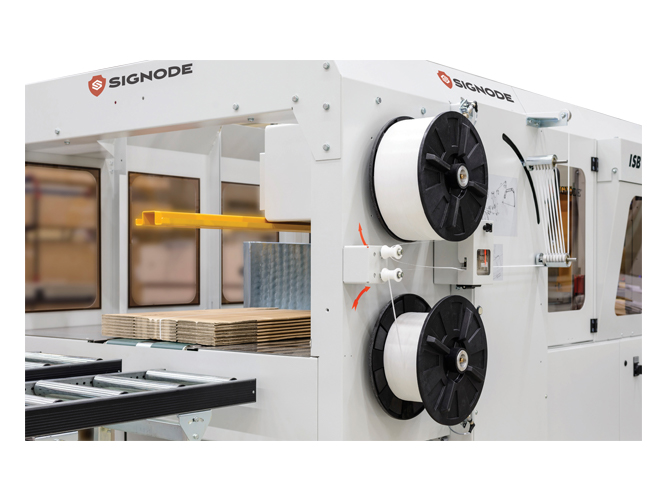

Packaging Lines for Corrugated

Offering a wide range of corrugated packaging solutions designed to optimize efficiency, protect products, and support facility automation. Systems include:

- High-speed bundlers including the SIG-CORR and ISB

- GCU™ Unitizers for compressing and securing loads

- Provide Octopus® stretch wrappers and Lachenmeier® stretch hooders for load containment.

- Protective packaging to meet diverse industry needs, all aimed at reducing damage, improving sustainability, and streamlining logistics

End-of-Line Machinery for Construction

Providing robust packaging and load securement solutions tailored for the construction industry. Including stretch wrapping and hooding systems like Octopus® ring wrappers and Lachenmeier® stretch hooders to protect materials from moisture, dust, and rough handling. Also offering plastic and steel strapping for bundling and securing heavy loads such as steel beams, concrete blocks, and rebar.

Our solutions are designed to improve handling efficiency and provide product integrity during storage and transport, even during storage in harsh outdoor environments. We work closely with you to find how end-of-line packaging can be suitably rolled out to meet the needs of your construction business.

Lumber focused Equipment

Protect lumber products during transport and including storage while improving operational efficiency. Providing a full solutions range which include compression strapping machines known as a Lumber Press, for use with Tenax® PET Strap and that can be equipped with batten applicators while utilising edge protection to secure and safeguard lumber loads.

We also provide automated bundling machines, top sheet applicators, and high-speed lumber marking systems for direct-to-product printing and labelling & marking, Signode is a one stop provider of solutions for lumber packaging.

We cater to many more industrial applications including, pharmaceutical, food and beverage, cottons, fiber & textiles, printing, logistics and general manufacturing / engineering. No matter your needs to prepare for shipment and distribution Signode can assist.