HLS

Heavy Duty Design

Built with a box type column and steel structure the HLS is a strong stretch machine

High Uptime & Efficiency

High uptime, high reliability POB rollers for the turntable provide additional low noise pollution

Pallet Sensors

Automatically detects the height of the pallet with automatic pallet height sensors

Pre-Stretch Up to 300%

Signode powered pre-stretch variable up to 300%

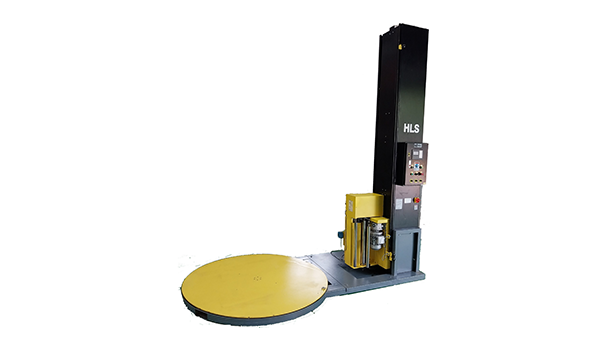

HLS Sensor Stretch Wrapping Machine

Introducing the HLS by Signode, a powerful semi-automatic turntable stretch wrapping machine designed to optimize your packaging operations. The HLS is built to withstand heavy-duty applications, ensuring reliable performance even in demanding environments. With AC drives and motors, this machine minimizes maintenance requirements, allowing for smooth and uninterrupted operation.

The Signode powered pre-stretch feature enables up to 300% stretch, maximizing the utilization of stretch film and reducing material costs. The automatic pallet height sensing is precise and provides consistent wrapping, eliminating the need for manual adjustments. The PLC control system provides easy programming and customization, allowing you to monitor and adjust stretch performance according to your specific needs.

HLS wrapping machine also offers a reinforcement wrap function, enhancing the stability and security of your palletized loads. With a generous 2.6-meter wrapping height, this machine is suitable for wrapping high cube containers, providing efficient and comprehensive coverage. Experience the advanced features and exceptional performance of the HLS from Signode and revolutionize your packaging process.

Features & Benefits

- Powered pre - stretch up to 300%

- Automatic pallet height sensor

- Reinforcement wrapping functions at any height

- POB turntable rollers for quiet operation and durability

- Easy film loading through pre - stretch unit

- User friendly push button operator controls

- Tilting feature for ease of installation and transportation

- Machine will not run, without pallet/ load

- In-built cutter for film cutting operation

- In-built Emergency stop and LOTO

Technical Specifications

| Machine Dimensions | |

|---|---|

| Length (mm) | 2900 |

| Width (mm) | 1610 |

| Height (mm) | 2800 |

| Weight (Kg) | 700 |

| Pallet Dimensions | |

|---|---|

| Length (mm) | 1135 Max |

| Width (mm) | 1135 Max |

| Height (mm) | 2600 Max |

| Weight (Kg) | up to 2000 |

| Wrap Height | Turntable Surface |

| Utility Requirements / Electrical | |

|---|---|

| Power | 230 VAC, 1-Phase, 50 Hz, 16A |

| Consumption (kw) | 2.0 |

| Controller | PLC |

| Height Detection | Photo Eye |

| Stretch Information | Digital Text Display |

| Speed Control | VFD |

| Turntable | |

|---|---|

| Load Per Hour | Up to 30 |

| Turntable Speed | 9 RPM |

| Turntable Diameter (mm) | 1605 |

| Turntable Rollers | High resistance POB |

| Turntable Drive | Chain and Sprocket |

| Turntable Motor | 1.0 HP, 415 VAC, 3- Phase, 50 Hz |

| Turntable Height (mm) | 85 from ground |

| Film Information | |

|---|---|

| Pre-Stretch Type | Powered |

| Film Stretch | Variable up to 300% |

| Film Roll Width (mm) | 508 |

| Film Roll Diameter (mm) | 254 |

| Core Size (mm) | 76.3 |

| Film Tension (kg) | 0.5 Min |

| Carriage Speed | Adjustable up/down through VFD |

| Pre-Stretch Motor | 0.5 HP, 415 VAC, 3-Phase, 50 Hz |

| Elevator Mode | 0.5 HP, 415 VAC, 3-Phase, 50 Hz |

*Ramp will be supplied for ease of Loading & Unloading of Pallets

*Standard machine designed for Stretch Film of 21 to 29 μm,

Option available for increasing it to accommodate 51 μm

*Options available - Safety Fencing, Horse shoe & weighing scale