StorFast® Automated Storage and Retrieval Systems (ASRS)

Automated Storage and Retrieval Systems (ASRS) for Modern Warehouses

The StorFast product portfolio consists of high-density Automated Storage and Retrieval Systems (ASRS), and a full range of material handling systems including robot-based depalletizing, palletizing and conveying solutions. Providing superior cost and performance advantages over other traditional warehouse systems for load handling and order picking across storage locations.

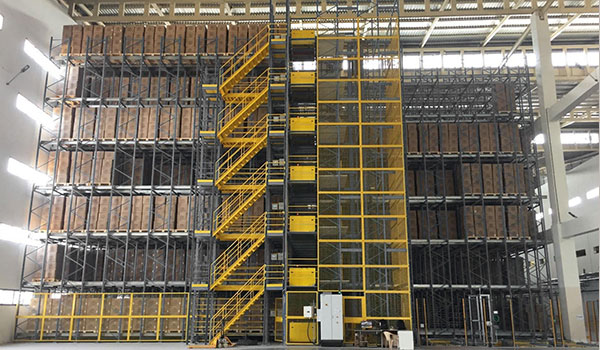

ASRS is an innovative cart-based storage solution featuring powered carts that automatically and efficiently move pallets in and out of storage positions. Designed as a fully integrated warehouse automation system, Signode’s ASRS maximizes operational savings, optimizes space utilization, and streamlines supply chain processes. The system is combined with logistics management systems to streamline warehouse operations.

Our ASRS solution delivers the following benefits:

- Optimizes Space Utilization: Modular design with unlimited configurations, providing a storage solution that maximizes floor space.

- Simplifies Maintenance: Standard components improve parts availability and streamline repairs.

- Increases Versatility: System allows for easy expansion as capacity requirements change for handled loads.

- Maximizes Volume: Achieves higher throughputs with significantly more storage than traditional systems.

Frequently Asked Questions

An Automated Storage and Retrieval System (ASRS) is a high-density, automated solution designed to store and retrieve goods with precision and speed. At Signode, our ASRS solutions help warehouses maximize space utilization, improve inventory accuracy, and reduce manual handling, making operations safer and more efficient.

Unlike conventional racking and manual picking, ASRS systems from Signode provide real-time inventory control, automated retrieval, and space optimization. This translates to lower operational costs, improved safety, and scalability for growing businesses.

- Optimizes space

With modular construction and a high level of adaptability, the StorFast ASRS storage system works within building constraints to optimize space regardless of layout and floor plans. The result is condensed space requirements for new warehouses and maximization of utilization within existing buildings, reducing the need for relocation or new construction. - Simplifies maintenance

The warehouse automation system is constructed with standard components, improving parts availability, maximizing uptime and simplifying maintenance. They feature controlled access to each level to support requirements for maintenance and inspection. - Increases capacity, an ideal inventory management system

Compared to traditional automated storage systems and manual racking, StorFast ASRS system provides a fully automated retrieval system provides significantly more capacity in a smaller footprint. The modular design allows for a wide variety of setups, this coupled with other features like deep lanes for pallet density and no height restrictions allows for full space utilization to provide maximum capacity for both simple and challenging configurations. - Pallet throughput

The system operates at an extremely high throughput from the simultaneous use of multiple machines. With individual cart movement, energy consumption is far lower than crane-based systems. This system provides the ability to store items with greater efficiency maximizing storage density when using the storage and retrieval system.

Signode offers more than just automated storage and retrieval systems. Our comprehensive portfolio includes palletizing, strapping, wrapping, and labeling solutions, enabling seamless integration of ASRS into a complete end-of-line packaging system. With our system approach, we ensure all components work together for maximum efficiency, and our dedicated team provides customized recommendations for optimal performance and sustainability.

Signode’s ASRS solutions are ideal for e-commerce, manufacturing, food & beverage, and distribution centers, any operation that requires high-density storage, fast order fulfillment, and reduced labor dependency. Discuss with our team how we can look to integrate into your facility.

Logistics Management Systems

The StorFast ASRS warehouse system delivers an intelligent logistics management solution by integrating with order management, warehouse management and order fulfillment systems. The system offers a fully customizable logistics solution to enhance throughput to meet customers’ demands and to optimize operational resources.

Order ManagementReceives customer orders and initiates process for fulfillment. |  | Order FulfillmentConfirms products from warehouse to sorting and picking systems to validate orders are filled as required. |

|  | |

Warehouse ManagementDetermines which products are required for fulfillment and defines inventory rules. |  | StorFast Storage/Retrieval SoftwareDetermines which pallets to retrieve based on inventory rules and replenishes high volume locations as required. |

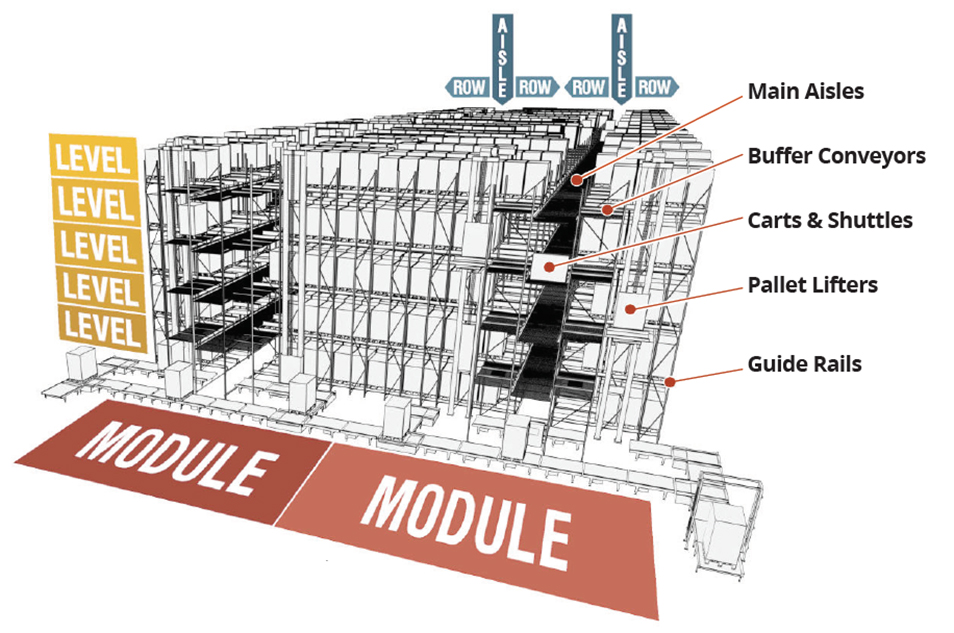

The Major Components of the Storfast ASRS Solution

The StorFast system is comprised of a distributed guide-rail storage system called Modules. Each storage Module has multiple levels and within each level is a network of central main aisles with multiple rows located on the right and left sides for storage and retrieval of pallets.

Operating on the main aisle of every module level is an Aisle Cart that carries a companion Row Shuttle that undocks to navigate the many rows.

The Aisle Cart and Row Shuttle are all-electric powered vehicles for automatically storing and retrieving pallets. row access is flexible to provide pallet position optimization and allow for changes in volume and prioritization, such as seasonal or new product updates.

The key fundamentals:

- An Aisle Cart transports a pallet to (or from) an assigned row

- The Row Shuttle then undocks carrying the pallet to store (or retrieve) from a specific row position.

- The movement of both the cart and shuttle is automatically controlled by system software using Programmable Logic Controller (PLC) technology communicating to a main controller.

- Carts and shuttles are equipped with Human Machine Interface (HMI) control panels. This HMI allows the operator to verify the current state of the vehicles, modify parameter, etc.

- The solution be combined with horizontal carousels and other automation technologies to create a fully integrated warehouse system, enhancing throughput and maximizing space utilization.

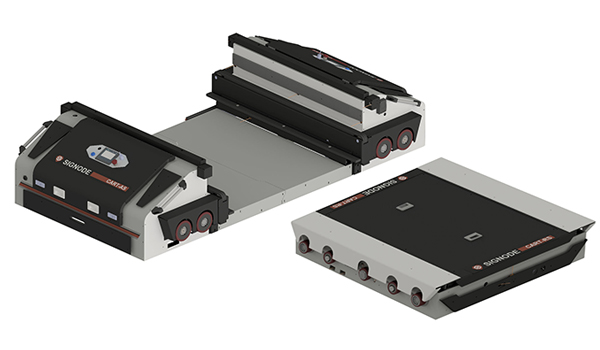

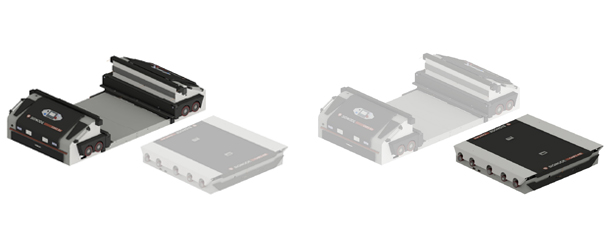

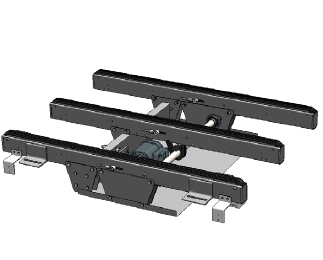

Aisle Cart

The Aisle Cart moves the palletized loads along a central aisle on each level. Its primary function is to transport the Row Shuttle with or without a pallet. The Aisle Cart loads pallets to or from the Buffer Conveyors by means of a chain conveyor. The Aisle Cart can be used to transfer a load from one row to another row on the same level, essentially acting as a vertical lift module.

Row Shuttle

The Row Shuttle handles the transportation of pallets in and out of the storage rows of each level. Row Shuttles are battery or ultracapacitor powered. The warehouse system rows are perpendicular to the central aisles of each level.

Each Row Shuttle uses two motors for travel and lift functions. The Row Shuttle is also equipped with PLC controls and wireless communication. When the Row Shuttle is docked inside the Aisle Cart (Home Position) the batteries are continuously charged for reliable performance.

Every Row Shuttle has simple “courtesy” controls for basic operations allowing the maintenance staff to manually operate the cart functions (raise, lower, backward, forward).

Aisle Cart show on the left and Row Shuttle shown on the right

Cart and Shuttle Features

- Powered by servo drive technology

- Up to 4400 lbs. (2000 kg) carrying capacity

- Modular design accommodates various pallet sizes

- All wheel drive for Row shuttles

- Designed for ambient, cold storage and deep freeze applications

- Row shuttles use two separate axis for transfer and lift

- Online communications between module control and all carts and shuttles

Pallet Lifter

Pallet Lifter

The Pallet Lift handles the vertical transportation of pallets in and out of the warehouse system. Pallets are supplied or retrieved from the various levels as required.

Only two motors are required for the Pallet Lift to function. A counterweight designed into the system reduces the amount of energy required to lift and lower loads and provides smooth operation. The transfer of the pallets on and off the lift is performed by the Buffer Conveyor.

The Features of a Pallet Lifter:

- Maximum load capacity: 4400 lbs. (2000 kg)

- Different available speeds and accelerations depending on the requirements of the system

- Pitless design, no underground components required in standard applications, unless extremely low level of the in/out conveyors or first level

- Special heavy duty lifting belt

Buffer Conveyor

Buffer Conveyor

The Buffer Conveyor is installed at every level. The Buffer Conveyor accepts pallets from both the Pallet Lift and Aisle cart and holds the pallets for transfer.

This allows the Pallet Lift and Aisle cart to continue to the next task. The duplex chain design of the Buffer Conveyor provides smooth pallet transport and reduces the gap between machinery.

The features of a Buffer Conveyor:

- Quiet operation

- Fully adjustable speed

- Storfast Overview Video

- Signode Storfast Warehouse Automation Solutions Video