Sealing the Deal: Choosing the Right Carton Closure Method for Your Business

August 20, 2025

In the world of product packaging, the way a carton is sealed can make all the difference in terms of product security, efficiency, and overall customer experience. Whether you're shipping lightweight consumer goods or heavy industrial components, the closure method you choose affects not only the product’s integrity during transit but also your business’s bottom line.

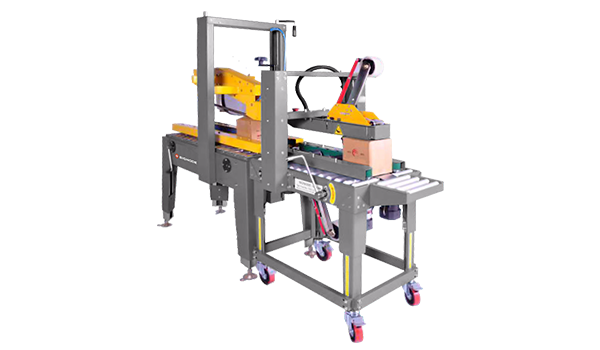

Tape Sealing

Tape sealing is a frequently used method for closing cartons, primarily due to its simplicity and low cost. It involves applying adhesive tape—either manually or automatically—over the top and bottom flaps of the carton. Various types of tape are available, including pressure-sensitive, reinforced filament, water-activated, tamper-evident, and paper-based options.

For businesses prioritizing speed and versatility, taping is a strong choice. However, it may fall short for heavy cartons or high-value items unless reinforced or tamper-evident tapes are used. Tape sealing is best suited for general-purpose applications where cost efficiency and throughput are key. Discover the broader benefits of effective carton sealing.

Stapling

Stapling is a mechanical sealing method that provides exceptional strength. Metal staples are driven through the carton flaps, creating a highly secure closure ideal for heavy-duty applications. While stapling may not be the most visually appealing option and requires tools or automated machinery, it’s extremely effective for bulky or heavy cartons that might otherwise open during transport.

However, it may not be suitable for consumer-facing packaging due to its industrial appearance and potential concerns for the user when opening the box.

Strapping

Strapping involves placing a plastic or metal band around the carton to keep it closed and stable. Often used in conjunction with taping or gluing, strapping provides additional support—especially for large, heavy cartons or those shipped over long distances. It’s ideal for maintaining carton shape under stacking pressure and for securing items that may shift during transit.

The downsides include higher equipment and material costs, as well as the extra time required for application. Nevertheless, for high-value or fragile shipments, strapping adds a crucial layer of protection.

Stretch Wrapping

While not a primary sealing method, stretch wrapping plays an important supporting role, particularly in palletized shipments. This method involves wrapping a stretchable film around a single carton or a group of cartons to provide stability and protection from dust, moisture, and shifting.

Stretch wrapping is best used as a secondary packaging method to supplement tape, glue, or strapping—especially in warehouse and logistics environments where products are stored and shipped in bulk.

How Do You Choose the Ideal Method?

When selecting a sealing method, businesses should consider several critical questions:

- How heavy is the carton? Is it likely to lose shape or open under stacking pressure or during transportation?

- How valuable are the goods inside? Is there a high risk of tampering or pilferage?

- What are your company’s sustainability goals?

- Do your packaging requirements call for tamper-evident, tamper-resistant, or tamper-proof solutions?

- Which method offers the best overall value? Consider not just material costs, but also productivity, equipment investment, labor, damage, returns, and potential pilferage.

The ideal sealing solution balances performance, cost, security, and sustainability based on your operational needs. For example, a high-volume e-commerce operation might favor automated tape applications for speed and cost efficiency, while a manufacturer of high-end electronics may opt for stapling combined with strapping for added security.

At Signode, we offer a comprehensive suite of carton sealing solutions tailored to various industries and packaging requirements. Whether you're looking for high-speed automation, tamper-evident packaging, or sustainable alternatives, we’re here to help you find the right fit for your business.

Carton sealing is more than just the final step in the packaging process—it’s a strategic decision that impacts product security, brand image, and profitability. By understanding the strengths and limitations of each sealing method, you can make smarter, more cost-effective packaging decisions.

Partner with Signode to develop a sealing strategy that protects your goods, enhances operational efficiency, and aligns with your business values. Let’s work together to create a fully integrated end-of-line packaging system. We incorporate technologies for packing, bundling, unitizing, and preparing products for transportation and storage.