Special Purpose Conveyors

Solution Group

- Products

- Services

- Integration

- Automation

-

pack

-

bundle

-

unitize

-

warehouse

-

transport

Regional Availability

We are developing systems dependant on your production lines requirements, we have multiple unique systems to streamline your manufacturing process. Our special purpose conveyor systems include:

- Board Inverter (Servo Motor)

- +/- 90° Slide & Turn Conveyor (Servo Motor)

- Servo Side Shuttle

- AOI Reject Conveyor

- Board Cleaner

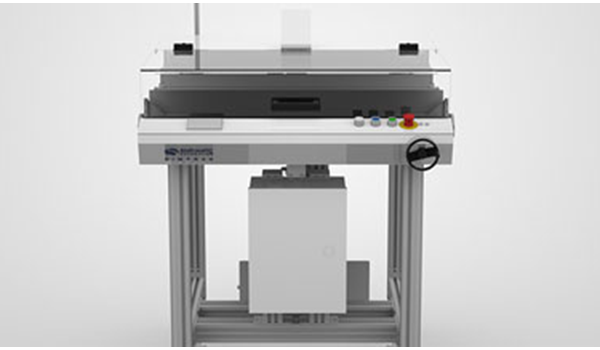

Board Inverter

Edge belt conveyor system that is designed to rotate flat panel products 180° around a horizontal axis. The system can also pass product through without inverting; accept, invert, and discharge from the same side; or invert and pass.

+/- 90° Slide & Turn Conveyor

The system is capable of rotating product 270° about a vertical axis. Depending on line configuration, product can be introduced or discharged from any side including same side in and out transfers.

Side Shuttle

This conveyor is used to convey product perpendicularly to the process flow where speed and routing options are primary concerns. Up to six positions can be taught, each capable of bidirectional transfer.

AOI Reject Conveyor

Allows printed circuit board manufacturers to easily isolate bad or rejected boards from production. Board rejection is based on up-line process input, typically provided by Automated Optical Inspection (AOI) systems.

The system uses pneumatically-controlled channels to carefully lift and remove PCBs from the line for secondary human inspection and rework without slowing down or stopping production.

Board Cleaner

Designed to function as a pass-through for Printed Circuit Boards (PCBs) and other electronic assemblies. While moving through the machine, a set of air knives remove particulate and other foreign material (FM) from sensitive electronics. This system is also outfitted with a cleanroom-certified vacuum to remove the debris from the system to avoid re-entrance onto the line.

Features & Benefits

Our special purpose conveyors are built to operate in high speed PCB electronic assembly lines.

- Solid belt construction manufactured from fiberglass-reinforced transmission

- Reliable stepper motors allowing for precise adjustments

- Premium rail design as conveyor features zero gaps between belt and edges to eliminate jams

- PLC options and can be configured for smart industry 4.0 communication

All our systems are designed according to your required specifications, reach out to our team to find out how we can integrate conveyor systems to improve PCB handling systems.

Solution Group

- Products

- Services

- Integration

- Automation

-

pack

-

bundle

-

unitize

-

warehouse

-

transport