Laser Marking for Printed Circuit Boards

Solution Group

- Products

- Services

- Integration

- Automation

-

pack

-

bundle

-

unitize

-

warehouse

-

transport

Regional Availability

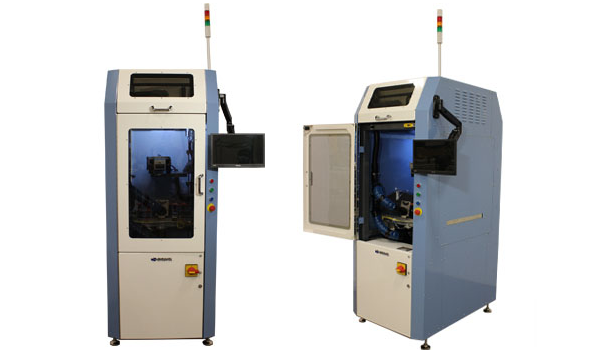

Focus on Simplicity

Machine design centered around simplicity

Robust Machine Design

Robust interface which can work well in lab or production environment

Multiple Capabilities

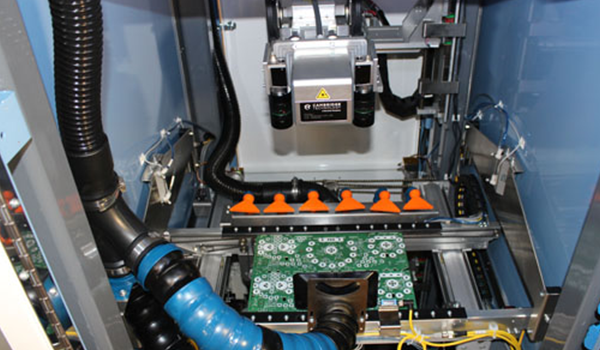

Top and bottom marking capabilities

Full Access to the Machine

Both upper and lower door swing open allowing full access to the lasers and other peripherals

Laser Marking

Highly-precise markers which are used to permanently etch alphanumeric characters, 1D and 2D codes, barcodes, and graphics files. This system has fully integrated PC controls with a decoupled laser and scan head. Inherent to the system is a robust machine interface that works well in a lab or in production environments.

Equipped with a configurable head combinations and programmable marking head height capable of marking the top and bottom of boards simultaneously. The flexibility with beam conditioning in this system is perfect for companies that want to protect their investment for total cost of ownership. This is a customizable platform that can be designed to customer specification.

Built with an industrial grade welded steel frame with metal skins attached that are light tight. The industrial grade welded frame provides us with the structural integrity needed to mount all desired components for the widest range of marking applications.

The Board Handling Capabilities of Laser Etching Equipment:

- Edge clearance: 3mm or 5mm (.11” or .19”)

- PCB max length: 508mm (20”)

- PCB max width: 457mm (3-18”)

- PCB Thickness: up to 7mm (.27”)

- Allowable warpage: 0.007”per in, 0.125 Max

- Marking area: 300mm x 300mm (11.81”x11.81”)

Footprint and Facility Requirements

- 3.9’ (1.2m) in length

- 2.6’ (.8m) in width

- 8.5” (2.6m) in height

- Electricity: 200-240VAC, 30A

Standard Features

- High-speed servo motor conveyor

- 30-watt CO2 laser - air cooled laser, decoupled laser/scan head combinations

- Windows 10 operating system

- Full-size touchscreen with keyboard

- SMEMA compliant

- Alpha-numeric, 1D and 2D code marking, human readable

- Custom mark library

Optional System Upgrades

- Multi-plane marking capability

- Lan compatible

- Single or dual laser scan heads

- Configurable with top and bottom marking capability

- Configurable laser/head combinations

- Servo controlled laser focal distance

- Small footprint (2.6’ X 3.9’).

- "X" expansion using shuttle axis capable of 550mm X 300mm

Solution Group

- Products

- Services

- Integration

- Automation

-

pack

-

bundle

-

unitize

-

warehouse

-

transport

Improve your manufacturing throughput, your facility’s efficiency, processes, repeatability and let you have traceability over your products and steps in your manufacturing line.