End Sealing Pallet Strapping Machine

Solution Group

- Products

- Services

- Integration

- Automation

-

pack

-

bundle

-

unitize

-

warehouse

-

transport

Regional Availability

High Level of Productivity

Machine design allows for no miss strap feeding, the strapping mechanism happens only via linear movements via the pull principle

High Speed Strapping

A short strapping cycle time provides high throughput

Minimise Line Stops

The freestanding frame is able to be placed outside the machine fencing providing 100% flexibility in dispenser positioning. The machine has low maintenance costs

Easy Integration in Packaging Line

Simple to integrate the palletizer into new or existing packaging lines

End Sealer Strapping Machines

Solution Group

- Products

- Services

- Integration

- Automation

-

pack

-

bundle

-

unitize

-

warehouse

-

transport

End Sealer Models

Signode offers five End Sealer models including the HC2M, HE Series, HE1M-AB, and HE1M-V designed to meet the unique demands of modern packaging lines. Each of our models are specialised in engineered for specific applications in horizontal, vertical, or combination strapping. Each model is specially designed for specific needs and industries, from beverage crates and glass bottles to construction materials, furniture, and logistics, End sealing equipment delivers secure, economical strapping for every industry.

Technical Specifications

| HC2M | HE Series | HE1M-AB | HE1M-V | |

|---|---|---|---|---|

| Strap Tension (N) | 0 - 400 | 0 - 400 | 0 - 400 | 0 - 400 |

| Machine Weight (Kg) | 900 - 1100 | 600 - 800 | 700 - 1000 | 600 - 800 |

| Strap Width (mm) | 5 - 16 PP or 5 - 13 PET | 5 - 16 PP or 5 - 13 PET | 5 - 16 PP or 5 - 13 PET | 5 - 16 PP or 5 - 13 PET |

| Sealing Method | - | Heat seal | Heat seal | Heat seal |

| Strapping cycle time per strap | Approx. 15s | Approx. 6s PP, 7s PET | Approx. 6s PP, 7s PET | Approx. 5s PP, 6s PET |

| Vertical Speed (mm/s) | 100 | 100 | 100 | 50 |

| Minimum strapping height (mm) | 1700 | 40 to 550 above floor | 40 to 350 above floor | 40 to 350 above floor |

| Maximum strapping height (mm) | Up to 2600 | Up to 2700 | Up to 2900 | Up to 1500 |

| Strap end | Strap-end detection by photocell | Automatic strap end detection | Automatic strap end detection | Automatic strap end detection |

| Dispenser | Separate strap dispenser with tow coils: flexible location | Separate strap dispenser with two coils; flexible location | Separate strap dispenser with two coils; flexible location | Separate strap dispenser with two coils; flexible location |

| Pneumatics | - | 6 bar / 95 psi, Approx. 85 I/Cycle | 6 bar / 95 psi, Approx. 95 I/Cycle | 6 bar / 95 psi, Approx. 75 I/Cycle |

End Sealers for Multiple Industries

End Sealing Strapping Machines can be used for many industries including:

- Beverage (Crates, Kegs, PET Bottles, Cans)

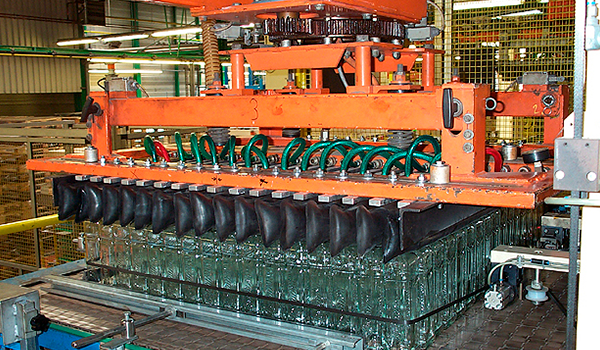

- Bottle (Glass)

- Construction (Paving Stones, Bricks, Roof Tiles, Ceramic Tiles)

- Food

- Can

- Cable

- Logistics

End Sealer Strapping Beam

The HE1D is a horizontal beam which is integrated into end sealing strapping machines and utilises 5 – 16mm strapping. The product pushes past the seal and the strapping machine brings the strap around the back, tensions then seals. At the same time a second seal is made which becomes the front of the next strap. This process is proven to reduce total cost of ownership and improve production uptime considerably.

Benefits of End Strapping Machines:

- The strap is applied by the movement of the product allowing for accurate strap positioning

- Soft strap application for delicate or soft products

- Smoother strap application on the product, minimising product damage

- Very thin narrow straps can be used to save consumable materials

- Fewer moving parts and no strap feeding means reduced downtime.

- Easily integrated into existing production lines

- Fast & reliable, with short cycle times (5–7 seconds) for high throughput.

- Low cost efficiency as works with smaller strap dimensions, lowering consumable costs.

- A flexible machine can handle diverse product sizes and heights with precision strap positioning.

- Simple to integrate into existing or new lines.

Strapping Beam Technical Specifications

| HE1D Horizontal Strapping Beam | |

|---|---|

| Strap Tension (N) | 0 - 400 |

| Machine Weight (Kg) | 300 - 400 |

| Strap Width (mm) | 5 - 16 PP or 5 - 13 PET |

| Sealing Method | Heat Seal |

| Strapping cycle time per strap | Approx. 6s PP, 7s PET |

| Tensioning stroke | Flexible, adapted to the product |

| Strap end | Automatic strap end detection |

| Dispenser | Separate strap dispenser with two coils: flexible location |

| Pneumatics | 6 bar / 95 psi, Approx. 85 I/Cycle |

Strapping End Sealers in Focus

View each of our end sealing strapping models.

HC2M Combination End Sealer

HE Series Horizontal End Sealer

HE1M-AB Horizontal End Sealer

HE1M-V Horizontal End Sealer