Simplimatic® Robotic Palletizers & Depalletizers

Robotic palletizing and depalletizing systems streamline end-of-line packaging by automating pallet loading and unloading. Our solutions include multi-axis robots and collaborative robots, designed to improve efficiency, reduce labor costs, and handle products of all shapes and sizes.

Automated Palletizing Solutions

Simplimatic® robotic palletizing systems are automated solutions to streamline your operations. These systems can be used to palletize a wide range of products, including boxes, bags, and cartons.

Automatic palletizing systems consist of a robotic arm, a controller, and a palletizing tool. The robotic arm is used to pick and place products onto a pallet. The controller is used to program the robotic arm and to monitor its performance. The palletizing tool is used to grip and move products.

Our full line of collaborative robots cater to high payloads, a varied size of products, different cycle time and precision when caring in your products.

Applications for Palletizers & Depalletizers Solutions

Our palletizers can be used across a broad range of industries including:

- Packaged food and beverage

- Bulk products

- Personal healthcare

- Medical

- Consumer goods

- Household appliances

- Cosmetics and many more...

All Simplimatic® palletizers and depalletizers are available with custom recipes to allow them to perform to differing SKU's and variable stacking patterns. Our automated palletizing solutions are easy to use, support your business increasing throughput, minimise costs and a custom programmable.

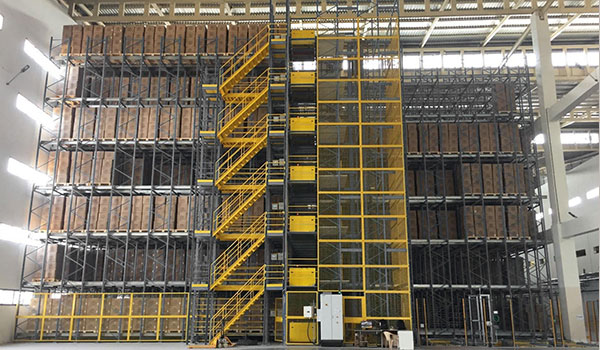

Automate Pallet Stacking

Engineered to your speed, payload, and footprint, stack pallets with Signode’s Simplimatic® automated pallet stacker machines.

Frequently Asked Questions

Automates the process of stacking products onto pallets and removing them when needed. This reduces manual labor, minimizes downtime, and increases overall productivity by ensuring consistent, high-speed operations.

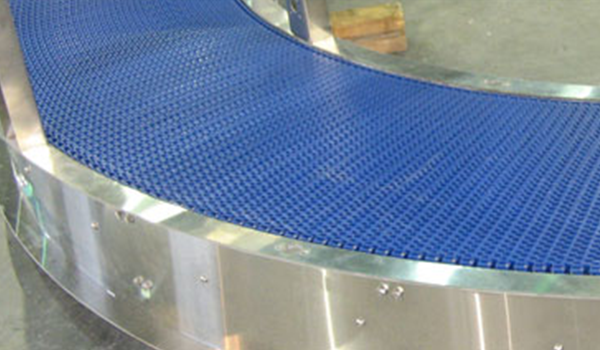

Signode’s robotic solutions are engineered for flexible integration. They can seamlessly connect with your current material handling systems, reducing the need for major infrastructure changes and ensuring smooth workflow continuity.

Providing several advantages, including:

- Increased Productivity: Automates palletizing and depalletizing to reduce downtime and labor costs.

- Flexibility: Easily integrates with existing material handling systems for smooth operations.

- Customization: Supports various end-effectors for different product types and applications.

- Safety & Reliability: Collaborative robots provide safe interaction in environments where humans and machines work together.

Finding the Palletizing Solution for You

Our robotic systems are easily integrated with new or existing material handling lines and other production line setups.

We provide robotic systems for a variety of industries and business cases; find out about the best solution for you by getting in touch with the Signode team to discover how our automation solutions can support your business.