Desiccants for Containers: Signode’s Hygro-Gel and Dri-Pack Solutions

November 11, 2025

Moisture damage during container shipping is a silent threat to global trade. Condensation inside containers, commonly known as “container rain” can lead to corrosion, mold growth, and packaging deterioration. For businesses shipping goods across varying climates, moisture control is critical.

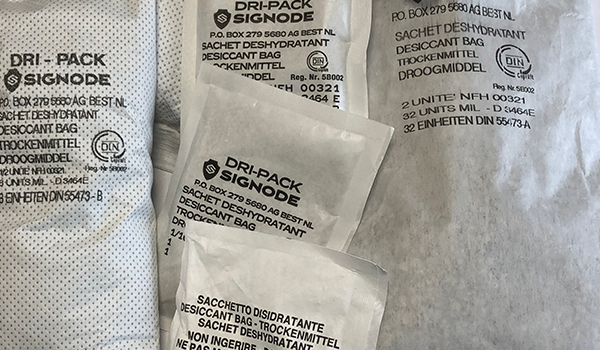

Signode offers two advanced desiccant solutions tailored this solution: Hygro-Gel and Dri-Pack. These products provide reliable protection against humidity and condensation, allowing cargo to arrive as expected.

Why Does Moisture Control Matter?

When containers travel through different temperature zones, humidity inside can condense on walls and ceilings. This water drips onto cargo, causing:

- Rust and corrosion on metal parts

- Mold and mildew on textiles and food products

- Packaging deformation and label damage

Our Desiccant Solutions

| Hygro-Gel | Dri-Pack | |

|---|---|---|

| Material | Calcium Chloride | Natural Clay |

| Absorption Capacity | Up to 360% of weight | Moderate |

| Leak Proof | Yes (Gel Conversion) | No |

| Best for | Long-haul containers with high humidity | Smaller packages for short transit |

When selecting the right desiccant make sure to calculate quantity according to the transit time, climate, and cargo type. The desiccants should be positioned vertically along container walls or under roof gaps. Consider using additional solutions, such as container liners for maximum protection.

Why Choose Signode?

Signode offers a comprehensive portfolio of end-of-line transit packaging solutions designed to protect your products throughout the supply chain. Our desiccant range delivers reliable moisture control for diverse applications from electronics to food products, providing cargo integrity during transit.