Modular Conveyors

Carton Conveyors

A collection of high-quality conveyor components designed to reliably transport bulk goods between processes during bottling, packaging, assembly, and a wide range of other manufacturing tasks.

Utilizing multiple frame types and chain styles, the carton conveyor provides customers with the ability to select a bulk-material handling system that is perfectly engineered to solve a project’s mass conveying needs.

Industry Specific Mat Conveyors:

Sanitary Mat

A rugged bulk conveying capabilities and utilizes clean-inplace design to accommodate caustic wash down for a variety of sanitary applications.

Painted Steel Mat

A durable carbon steel construction for bulk conveying in industries that do not require wash down. This mat top conveyor is customizable.

Stainless Beverage

A high-strength bulk conveying in applications that require occasional wash down, without the need to meet strict sanitation requirements.

Aluminum Conveyor

Light-duty bulk handling, utilizing a modular aluminum design. A reconfigurable system is simple to integrate and can be easily upgraded.

Reliable bulk conveying for all industries:

Solid Top Mat Chain

A thick surface offers long service life and chains using <1’’ pitch for smooth operation with minimal chordal action, dead-plate gap, and speed pulsation.

High Friction Mat Top Chain

A high-quality mat top chain with rubber-bonded top surface provides a friction top to prevent product slipping during conveyor incline and decline operations.

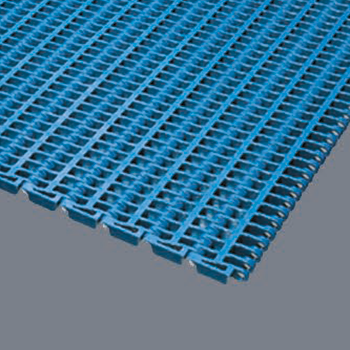

Perforated Top Mat Top Chain

Flexible chain module that provides a high-friction surface for incline or decline conveying while not interfering with the chain passageway in the facility.

Low Backpressure Mat Top Chain

A flexible chain is constructed using durable roller chain to allow for the accumulation of product between manufacturing processes.