SIG-N PLUS

Solution Group

- Products

- Services

- Integration

- Automation

-

pack

-

bundle

-

unitize

-

warehouse

-

transport

Regional Availability

Streamlines

Operation

User-friendly and intuitive design simplifies operation

Increases

Productivity

Up to 20 cycles per minute on the largest frame

Cost-efficient

Design

High efficiency design and components reduce operating costs

Minimizes

Maintenance

Robust design with low maintenance requirements

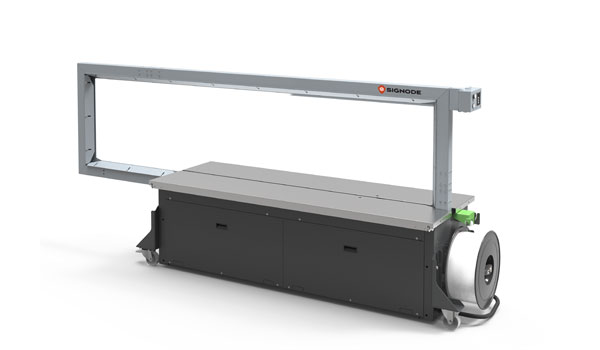

SIG-N Plus Strapping Machine

The SIG-N Plus inline strapping machine, ideal for wide and tall products including Gaylord boxes, provides high-speed bundling and unparalleled flexibility for the corrugated industry. The SIG-N Plus is an efficient, reliable strapping machine.

Features and Benefits

- Long-lasting efficient operation

The SIG-N Plus requires 50% less energy than conventional machines. With highly efficient drives and low friction mechanical components, the SIG-N Plus couples a unique chute system with an energy saving drive motor to help provide continuous, reliable performance. - Productivity-enhancing features

From automatic strap refeed to an anti-strap loss function, the SIG-N Plus is manufactured to maximize throughput while minimizing downtime. - Simplifies maintenance

The SIG-N Plus features direct access technology providing easy access to the strap, while helping to reduce an operator’s exposure to moving parts. Plus, a segmented strap chute with a lifetime warranty on the flaps and one wear part eliminate costly repairs and maintenance downtime. - Production flexibility

The SIG-N Plus is available with a number of options to suit different production requirements.

Optional Equipment

- Strap release sensor

- Footswitch

- Non-driven roller bed conveyors

- High-tension up to 600 N

- Interlock for system integration

Technical Specifications

| Cycle Rate Per Minute* | Up to 20 bundles per minute |

| Bundle Weight (Max) | 100 kg (220 lbs) |

| Strap Tension | Adjustable up to 325 N (73 lbs) |

| Strap Material | Polypropylene 5 mm − 12 mm (.197 in -.480 in) |

| Strap Seal Method | Heat seal |

| Electrical Requirement | 100-240V, 60 Hz |

| Maximum Shipping Weight | 330 kg (728 lbs) |

| Environmental Condition | 5° to 45° Celsius (41° to 113° Fahrenheit) |

*Cycle rate based on largest frame size

Machine Dimensions

| Chute Size W x H (mm) | Bundle | Machine Weight (Kg) | Total Height | |

| Width | Height | |||

| 2250 x 600 | 2250 | 600 | 325 | 1420 - 1505 |

| 2650 x 600 | 2650 | 600 | 335 | 1420 - 1505 |

| 2650 x 2650 | 2650 | 2650 | 380 | 3570 - 3655 |

Solution Group

- Products

- Services

- Integration

- Automation

-

pack

-

bundle

-

unitize

-

warehouse

-

transport