Monotub DD

Solution Group

- Products

- Services

- Integration

- Automation

-

pack

-

bundle

-

unitize

-

warehouse

-

transport

Regional Availability

Rapid Construction

The Monotub DD improves the speed of construction as erecting, pouring and removing of formwork can be done quickly

Reduce Costs

As delivery for all columns can happen at once, this reduces concrete costs

Simple and Lightweight

Monotub DD can be easily erected by one worker without the use of cranes

Sustainable

Manufactured from recycled waterproof carton, the product is 100% water-resistant and is built to withstand diverse weather conditions

Monotub DD

Monotub DD can be specified to your construction needs. Offering column protection, providing concrete curing. Easily positioned, removed and light-weight. Monotub can be stored outside due to it's weather resistant construction; this all-weather approach provides maximum flexibility on-site as it is not necessary to pour the concrete immediately after constructing the tubes. For optimum results it is advised to condense the concrete after every 50cm.

Monotub DD Range Features and Benefits

- Monotub DD Speed

An equal smooth column form which can be removed very quickly by pulling down the steel line that is the tube and functions as a 'zipper'. The inner foil (PVC) creates a slow maturing of the concrete, which benefits the strength of the concrete. - Monotub DD Spiral

The Spiral is suitable for dirty work, concrete assessment class 1 C. After the formwork has been removed, a spiral drawing will remain visible in the concrete surface. This formwork can also be made with a zipper. - Monotub DD Square/Rectangle

The form consists of the standard circular tube that is assembled with polystyrene parts. The product is finished on the inside with a hard inner plate. The square/rectangular version is suitable for concrete assessment class 1A/CUR 100. The tube is produced without a zipper as standard, as the tube can easily be cut open (with a knife or a grinder) on the polystyrene part without damaging the concrete surface. - Monotub DD Basic

The Basic is for infilling, often shorter pouring tubes. The tube is slid over the concrete pile head and poured with concrete. The pouring tube can easily be cut back to any length on site. The tube can also be delivered to the construction site in any desired length from the factory.

Type and Diameter

| Monotub DD Type | Diameter Range Available (mm) |

|---|---|

| Speed | 152 to 1200 |

| Spiral | 152 to 1200 |

| Square/Rectangle | 200 to 700 |

| Basic | 152 to 1200 |

Technical Specifications

Diameter (mm) | Concrete in dm per mtr Column | Surface Quality class of Concrete | Wall Thickness (mm) | Weight (Kg) per Meter of Tube |

|---|---|---|---|---|

| 152 | 18.1 | 1A | 2.5 | 1.3 |

| 202 | 32 | 1A | 2.5 | 1.7 |

| 250 | 49.1 | 1A | 2.9 | 2.1 |

| 300 | 70.6 | 1A | 2.9 | 2.5 |

| 350 | 96.2 | 1A | 3.3 | 3.6 |

| 400 | 125.6 | 1A | 3.7 | 4.1 |

| 450 | 159 | 1A | 3.7 | 4.6 |

| 500 | 196.3 | 1A | 4.1 | 5.1 |

| 550 | 237.6 | 1A | 4.1 | 6.3 |

| 600 | 282.7 | 1A | 4.5 | 6.9 |

| 650 | 333.8 | 1A | 4.5 | 7.5 |

| 700 | 384.8 | 1A | 4.5 | 8.0 |

| 750 | 449.5 | 1A | 4.9 | 7.5 |

| 800 | 515.3 | 1A | 4.9 | 9.3 |

| 850 | 582.85 | 1A | 4.9 | 9.5 |

| 900 | 650.4 | 1A | 4.9 | 10.5 |

| 1000 | 785.4 | 1A | 5.3 | 11.5 |

| 1100 | 958.2 | 1A | 5.3 | 12.5 |

| 1200 | 1131 | 1C | 5.3 | 13.7 |

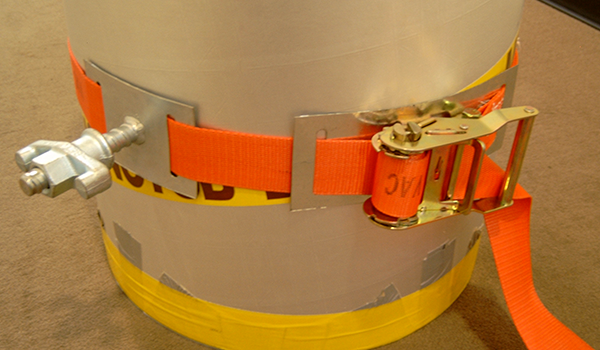

Monotub DD Accessories

Additionally available are accessories for Monotub DD, In order to complete the product the yokes for fixing and erecting can be provided. The bottom yoke is made out of recycled board and fits perfectly on the outside of the tubes, this product can be reused several times. Additional accessories include foot braces delivered in two parts for easy construction at the bottom of the tubes. The multistrap for adjusting and stabilising the column framework from the top can also be provided. The multistrap is a nylon strap which is attached to the column formwork supporting with stability.

Solution Group

- Products

- Services

- Integration

- Automation

-

pack

-

bundle

-

unitize

-

warehouse

-

transport